I’ve been doing my own plumbing for years, and once moved the hot water cylinder (part of a central heating system), cold water tank, and heating system header tank with no mishaps. That’s not to say there were no problems, and it ended up taking ages as I had to do the job using present day fittings and pipework on a system originating in the 1930, when sizing was different.

As per the previous post on this subject, I’m STILL coming up against this old sizing problem, and it’s ALWAYS a surprise because the old ½ inch pipe is almost completely visually indistinguishable from present day 15 mm stock. I noted previously that this difference had FINALLY made it into online discussions, but even those are far from helpful as they fail to cover many practical aspects, with ‘experts’ offering their advice as if it was absolute.

I pity anyone who is coming up against old ½ inch material for the first time, and comes across the plumbing forums and videos where the advice given is that there’s no significant difference between that and current 15 mm stock, and they go on to show (or claim to show – I think they may just be using all 15 mm stock) that old ½ inch pipe will fit straight into 15 mm fittings, and people are wasting their money buying ½ inch to 15 mm transitions.

They should come work in my house – not only does the old ½ inch pipe not fit any 15 mm copper hardware, a 15 mm olive will not slide onto the old pipe. Better still, a 15 mm securing nut will not slide onto the old pipe, despite having good clearance on 15 mm. Yet the ‘experts’ on video happily show olives and nuts sliding on (what the claim is ½ inch pipe) with a cheery “There you go, that’s how it’s done and no need for transition pieces”.

That’s not my problem, since I found the plastic version of a pushfit coupling has a tolerance that accepts the widest ½ inch pipe I’ve found in any of my old plumbing – stuff that won’t fit into a 15 copper fitting even when a large ‘persuader’ is employed (hammer for the uninitiated).

My problem is that I don’t seem to be able to get a drip/leak free fit on the 15 mm pipework – which is crazy!

All the fittings are new, although the 15 mm pipe is old, but is the same stuff I’ve been cutting anything I need from for years, with no problems.

I mentioned the accessibility problem in the last post – the work can’t be reached by kneeling and reaching under the sink (too far back); lying on one side is almost useless as that’s too low to reach up to the work. Propping up on one arm to reach it means you then only one free arm/hand which is obviously also largely useless as most tasks need two hands, one to hold the pipe/fitting and one to do something to it; that leaves sliding in on your back – this ALMOST works but for the fact that the base of the unit is raised – that puts an impossible arch in your back as your butt lies on the lower floor outside the cupboard – something I had to counter by building up the height of the floor to match the base. I could go on, for example all the sink and machine wastes are on one side, reducing the space still further) but hurt in too many places.

I know it will be considered arrogant to say I’m not the problem, and must be incompetent, but…

Given that I have replaced all the (compression) fittings, and even some of the pipework, I’m beginning to think the current batch of fittings I am trying to complete this job with are defective, or might have defective olives.

Although the accessibility problem means I had to cut some olives off in situ (so they are destroyed in the process), the ones I was able to remove and examine with the fitting don’t appear to show compression wear marks on their edges, which I usually see after they have been tightened. I found one only had a wear mark around 80-90% of its circumference, suggesting it was not even making full contact.

But, could I prove this if I took them back and complained?

Would there be any point?

Looking at the labels, I don’t see any batch identification numbers.

Better still – the labels say ‘Made in China’.

That’s not a dig at Chinese manufacturing (which seems to have become a popular sport), merely a reflection on the likely futility of raising the matter with the supplier.

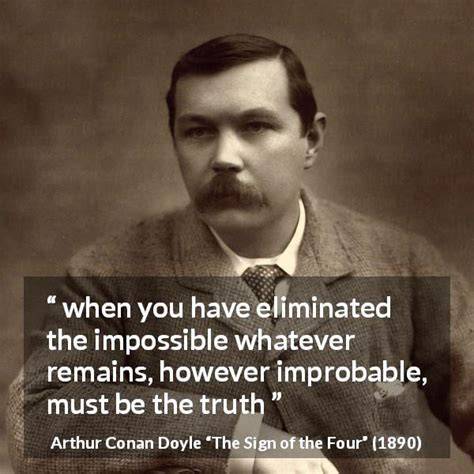

And THAT’s why the Holmes/Doyle reference appeared in the title – I’m pretty sure I’ve eliminated most of the sources behind my apparently incurable leaks/drips, something I never suffered from until I used up all my old fittings and had to go buy new ones recently.

Improbable Truth

After I replaced all the fittings for the first time, I just tightened all the joints to be snug – surprisingly there were no drips, at first. Some hours later, a few appeared and I started to tighten the fittings – about a quarter of a turn or less each time

THAT was apparently a mistake – far from securing the fittings and stopping the drips, this action turned them into proper leaks!.

I’m used to tightening a compressing fitting and seeing drips/leaks disappear – NOT get worse!

I’m reluctant to move towards overtightening these fittings – one of them already turns from drip to a small jet as it’s tightened.

In fact, I backed them all off slightly before giving up and going to bed last night – and the ‘leaks’ went back to be ‘drips’. When they were tighter, they’d fill a basin in a few hours – backed off, all I had was a few drops in the basin by morning.

Given the plastic pushfit I used for the ½ inch to 15 mm transition was ‘perfect first time’ on both sides, I picked up an equal T last night and, once my poor back recovers, will probably pull the lot out once again, check if the ends are fit to be used in that fitting, or cut new pieces to suit.

There is always the possibility that it has surface damage I can’t see by eye, although they were checked and cleaned before use.

Insert appropriate ‘Losing the will to live’ thought here – I cannot believe I have been trying to install what amounts to a T-piece for almost a week.

If I count the number of joints, installs, and re-installs I’ve done in that time, I could have replumbed the whole kitchen twice over!